Pipe Lifting System

Pipe Lifting System

A proven global solution for on-stream pipe inspection and remediation programs.

Ovolifts has a unique and patented technology developed in conjunction with the Petro-chemical industry for providing safe access to multiple pipe touchpoints in live environments.

Assuring Asset Integrity

Our pipe lifting systems enable inspection and corrosion prevention maintenance on multiple pipe touchpoints whilst the lines are on-stream and averts costly plant shutdowns or extended turnarounds.

Our pipe lifting tools are a key component of our lifting solution.

We have product and service portfolios that serve the entire fire and security market, integrating all verticals. We have a reputable reference base from the private sector to the industrial sector.

Quality, reliability, and efficiency are key driving forces in terms of the products and technology we import and distribute which forms part of our core business.

Our core business is project-based distribution, which focuses on Our pipe lifting tools are a key component of our lifting solution.

We work with your plant maintenance contractor to engineer a safe lifting solution, providing clearance between the pipe and the entire top section of the pipe support whilst the lines are in-service.

This gives free access at the pipe touchpoints to conduct maintenance in a single step. Our systems achieve lifting heights of up to 6” (project specific for greater heights), ideal to perform NDT, maintenance, or improvements.

Lifting is done remotely using hydraulic rams to avoid personnel exposure and risks. The lift is then vertically secured, declared a static structure (rather than a suspended load) and therefore safe to conduct work underneath.

- MEGA-JACK

Our Mega-Jack is the only pipe rack jack in the world capable of lifting very large pipes resting on ground-level supports. To execute these lifts otherwise would require a crane at a substantially higher cost and inefficiency.

It can lift single or multiple pipes from ground-level supports or pipe racks.

Specifications

- Lift individual or multiple pipes.

- Remote hydraulic lifting (optional).

- Manual lifting using ratchet.

- Double mechanical lockout.

- Lift selected pipes on a rack or skip pipes using shims.

- Lifts any diameter pipe

- Can lift pipes up to 4 inches from a H254 beam, custom lifting configurations can provide greater clearances.

- Handling weight is 44 lbs per arm.

- Safe max. lifting capacity is 44,000 lbs (20 tons) per touchpoint using two jacks, lifts more using additional devices.

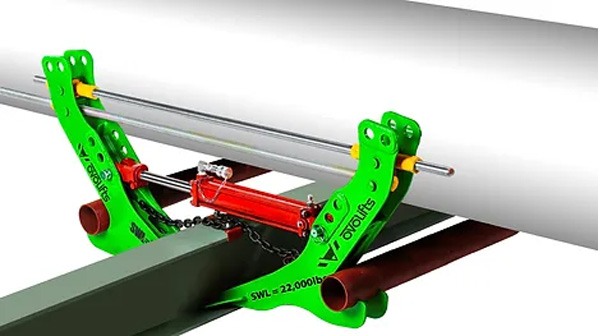

2. MULTI JACK

The Multi-Jack in its minimum configuration has a lifting capacity of 22,000 lbs (10 tons) from a single pipe support beam, and a higher tonnage if additional jacks are added to the lifting pipes.

This pipe rack jack has been purpose-built to lift single or multiple pipes across a rack easily with minimum installation effort and is a lighter, more versatile device than the Mega-Jack

Specification

- Lift individual or multiple pipes.

- Remote hydraulic lifting.

- Manual lifting using ratchet.

- Double mechanical lockout.

- Lift selected pipes on a rack or skip pipes using shims.

- Lifts any diameter pipe.

- Can lift pipes up to 4 inches from a H254 beam, custom lifting configurations can provide greater clearances.

- Handling weight is 24 lbs per arm.

- Safe max. lifting capacity is 22,000 lbs (10 tons) per touchpoint using two jacks, lifts more using additional devices.

3. UNI JACK

The Uni-Jack is a lightweight and portable pipe rack jack, purpose built for lifting individual lines at a time up to 8″ in diameter. It is exceptionally quick and easy to install while being sturdy enough to provide safe access to the touchpoint area.

This jack comes in 3 models; a 4″, 6″ & 8″ which can each lift their specified line size and all sizes smaller.

The lifting pipe features a load bearing and low friction Vesconite roller to prevent damage to the line being lifted and any protective coating, and its slender design allows it to fit with just 1″ of clearance between adjacent lines.

Each of the 3 models has a rated lifting capacity based on calculated line weight that assumes a ‘worst case’ support spacing, design & operating conditions and a 4″ lift height to ensure all lines of a specific diameter are within the lifting capacity of the jack model.

The jacks are activated using a light-weight hydraulic setup with a pressure gauge to ensure the correct amount of force is being applied to lift the line as per the Stress Analyses calculation.

Safely lifts upto 4″ from I-beam supports ranging in size from 4″ to 12″ in height with lifts being achievable from any other size and shape support. Please reach out to us with your specific lifting requirements and we can engineer a solution that works for you.

- Lift individual lines up to 8" in diameter.

- Remote hydraulic lifting.

- Manual lifting using ratchet spanner.

- Mechanical lockout.

- 4" standard lift height with 6" lift heights achievable.

- Handling weight is 11 lbs per arm.

- Lifting capacity sufficient to lift specified line size operating at maximum loading conditions.

Application

Our tools were designed to provide safe access to pipe touchpoints, no matter the pipe size, layout or type of inspection or repair procedure. .

Compromised Integrity At Pipe Touchpoints

- Failed Teflon Pads

Non-metallic pads are in most cases crucial for disrupting metal to metal contact between the pipe and support. This can lead to problems such as Corrosion Under Pipe Supports.

- Pipe Movement

Non-metallic pads are in most cases crucial for disrupting metal to metal contact between the pipe and support. This can lead to problems such as Corrosion Under Pipe Supports.

- Water Entrapment

One of the most prevalent challenges on piping systems is Corrosion Under Pipe Supports (CUPS) caused by water entrapment at the pipe touchpoint

- Liquid Hammer

Tremendous forces are at play during liquid hammer events which can cause significant pipe movement and corresponding damage, especially at the supports.

Foreign Technical Partners

Ready to Explore any of Our Services?

Our methodology manages the success of every project to guarantee that Clients’ expectations are always meet.